Cavitation – an almost unknown force. For many the unthinkable: Small water bubbles dissolve the most massive metal structures within a short time. Localized damages, virtually as sharp-edged as a laser beam. Indeed, the enormous bundling of energy is physically based on a little explosion followed by an implosion of the air bubble. And cavitation is just as loud – unmistakably similar to rockfall.

Metallic microstructures are susceptible to the permanent, shock-like alternating loads of compression and tension. Embrittlement is a fact of life. Thermal repair processes turn out to be additionally problematic here - the undesirable change in microstructure (hardening) can even aggravate the problem and additionally cause cracking!

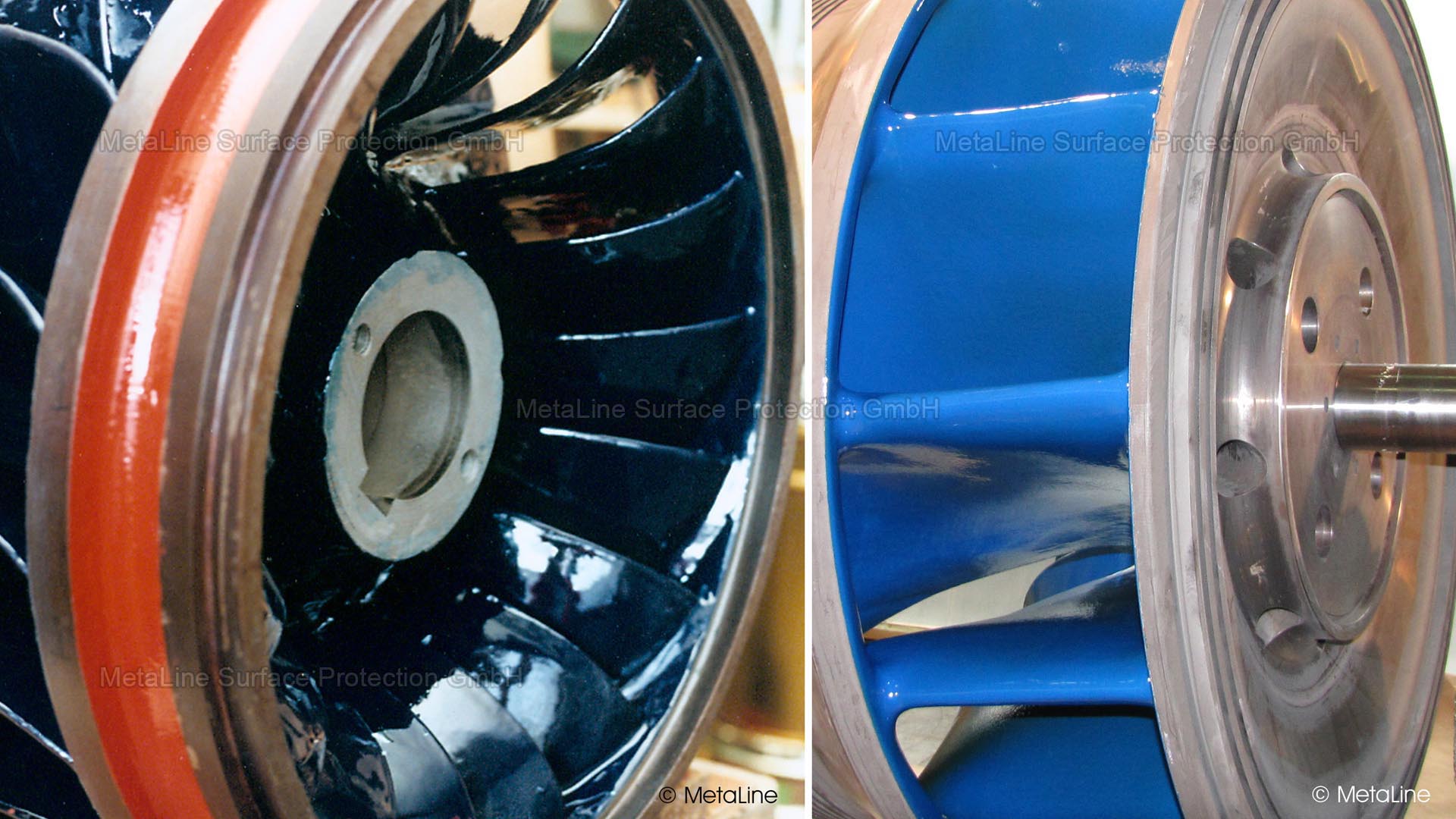

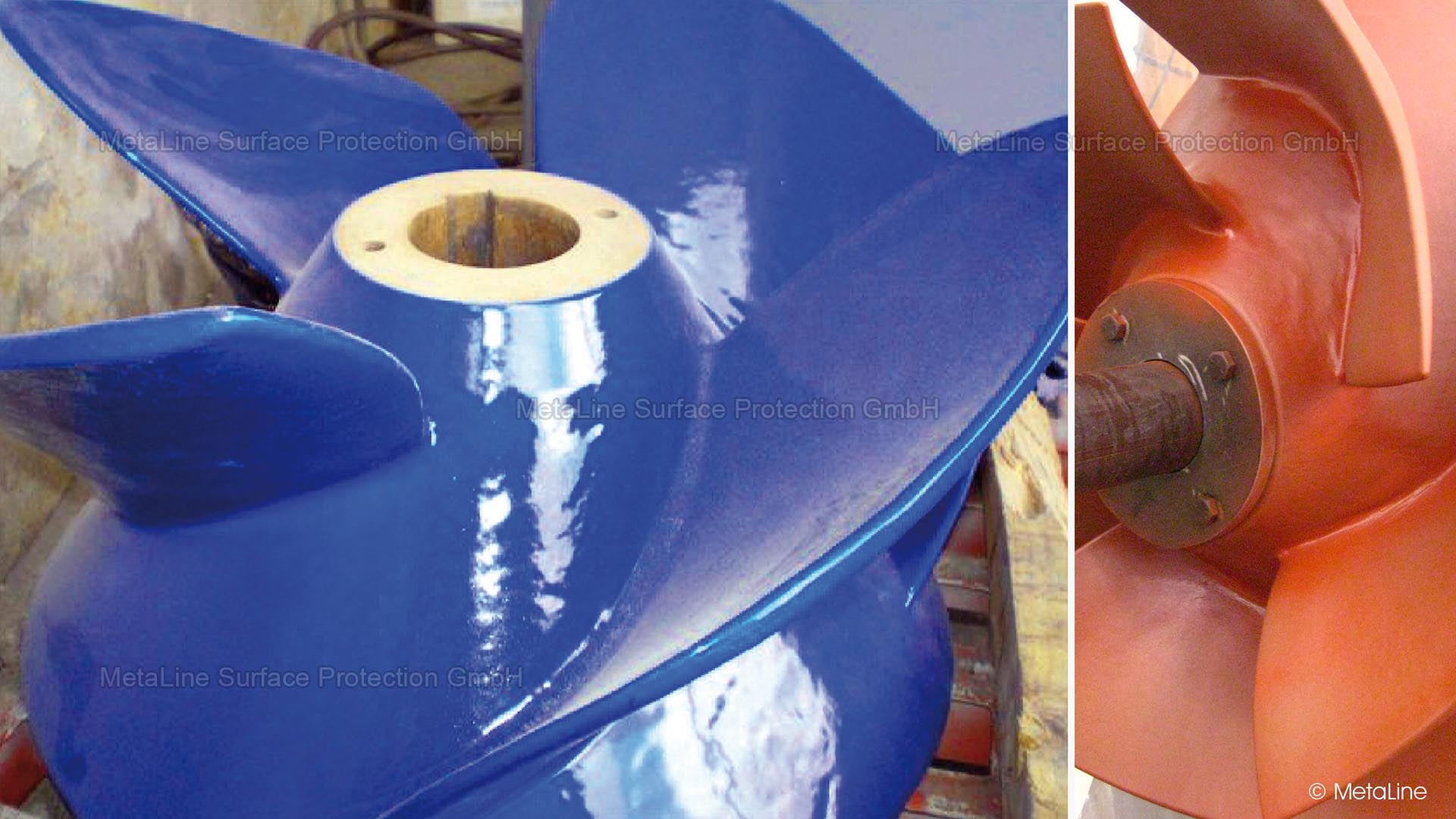

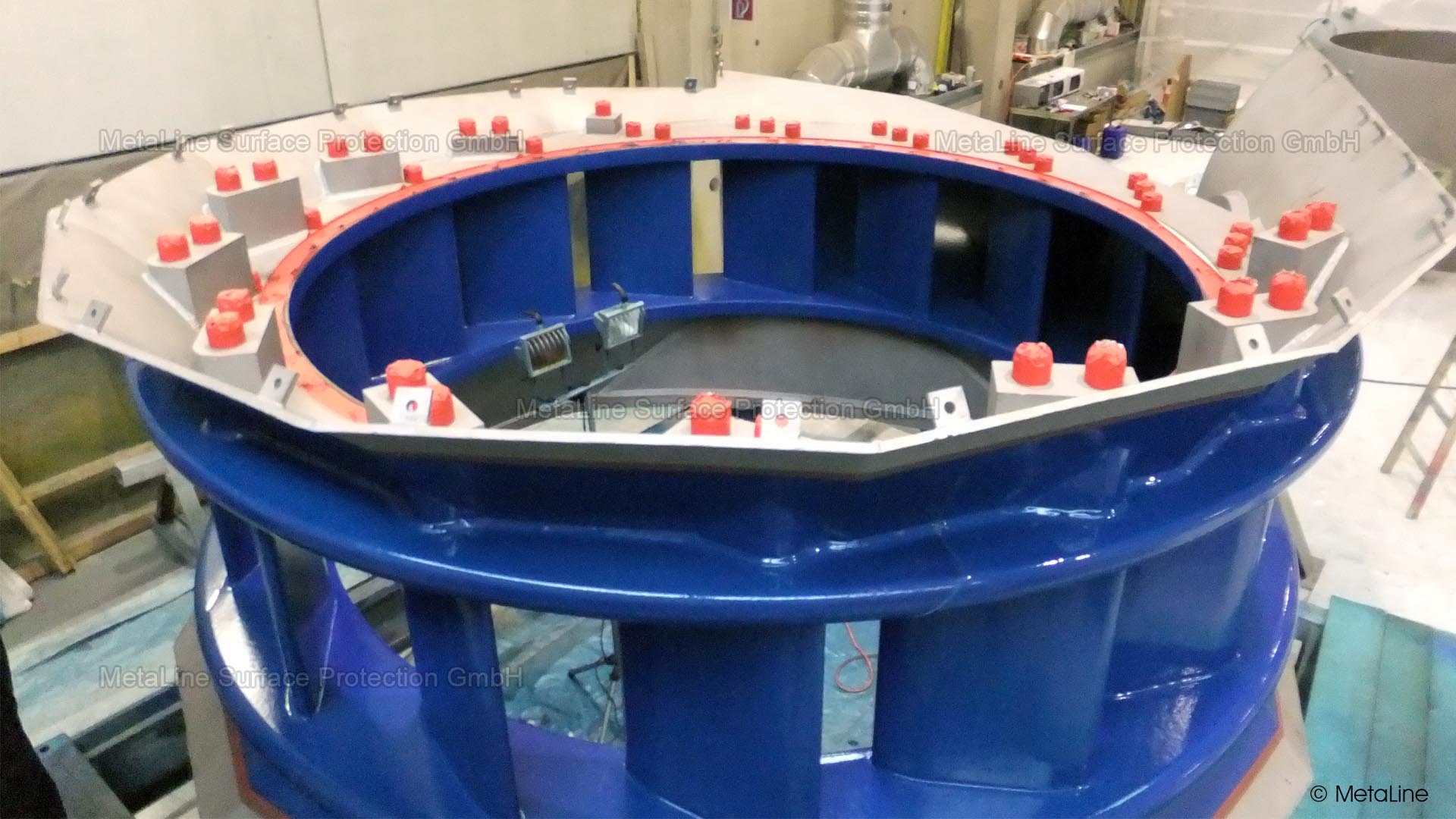

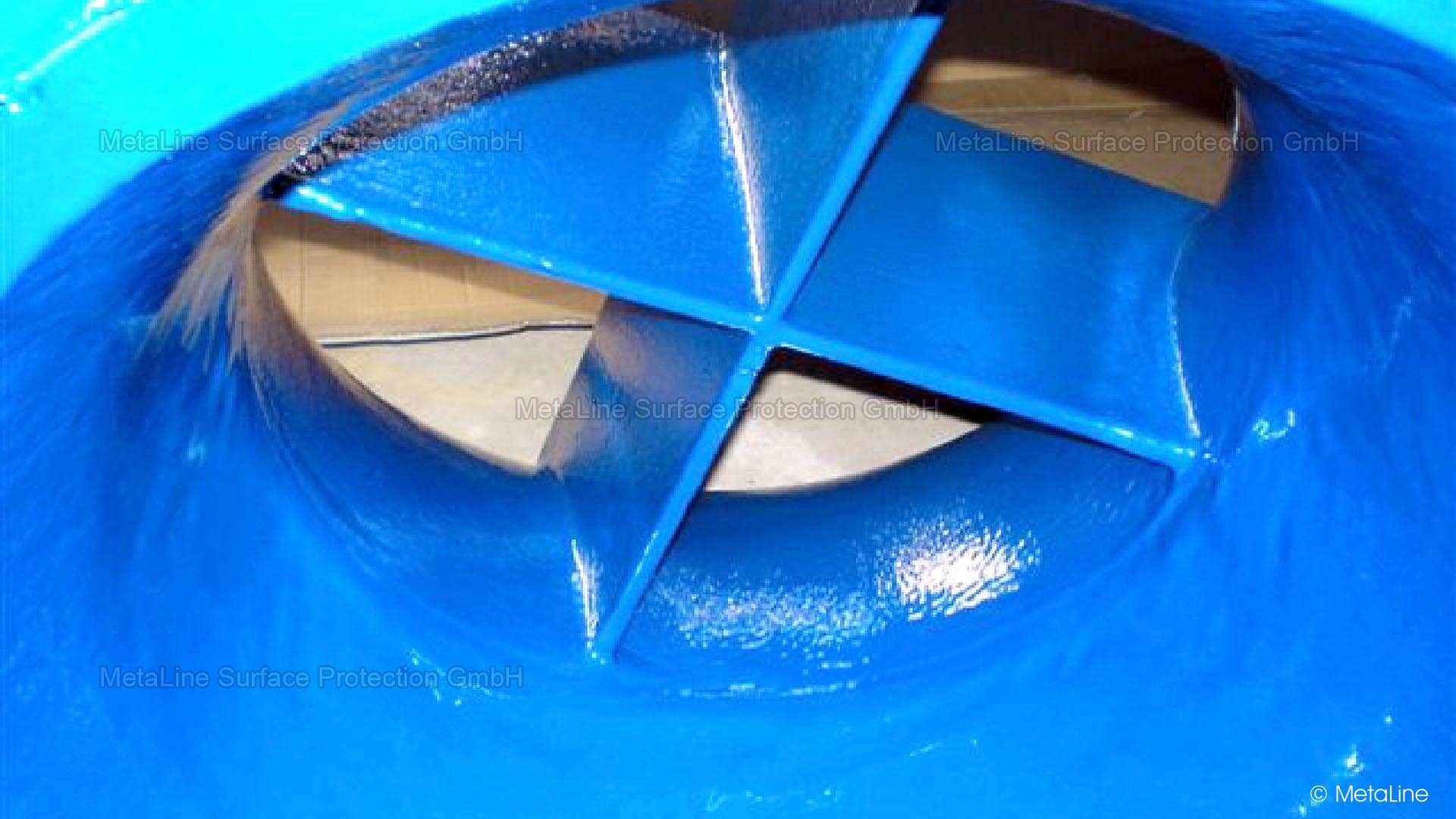

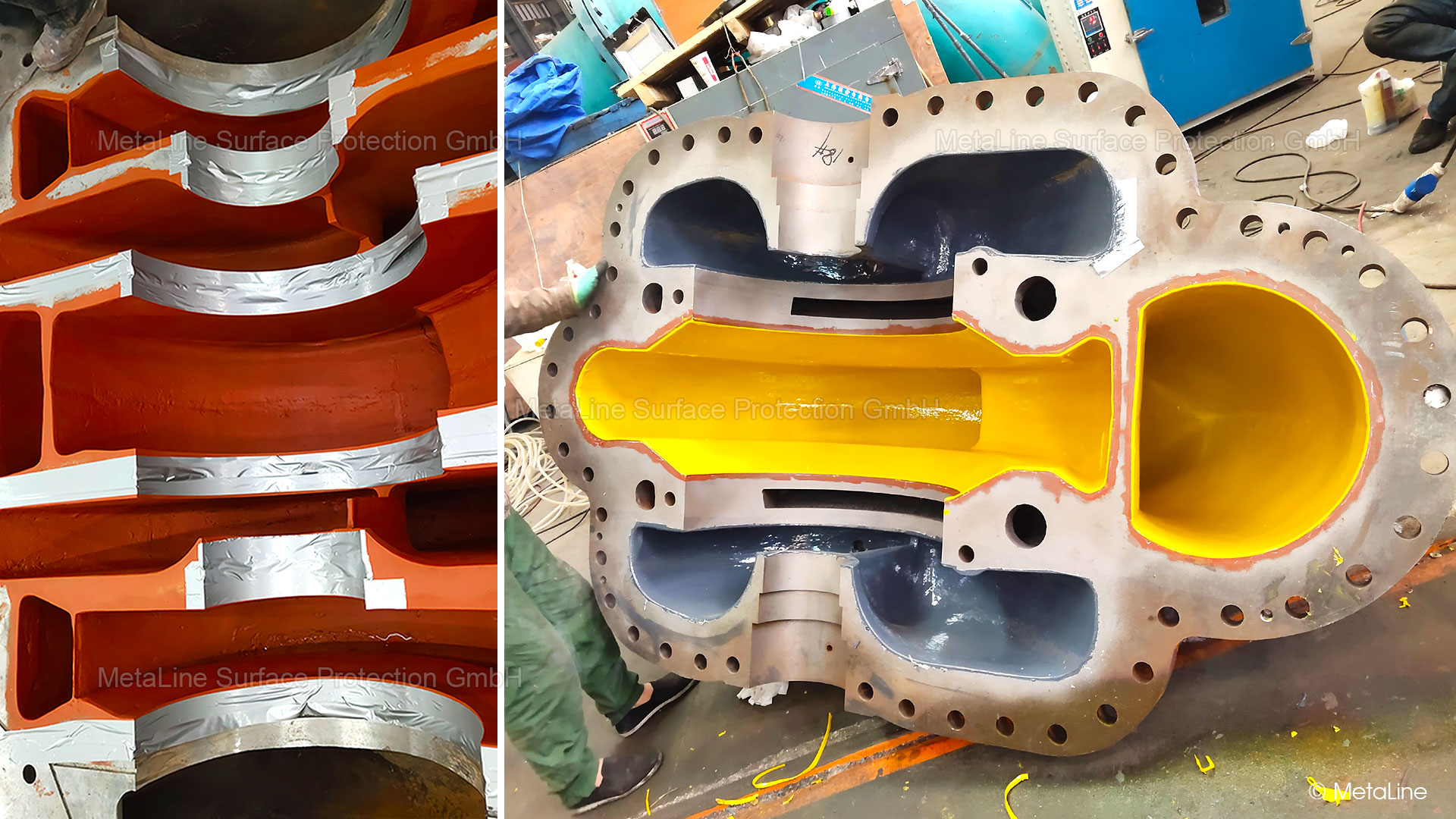

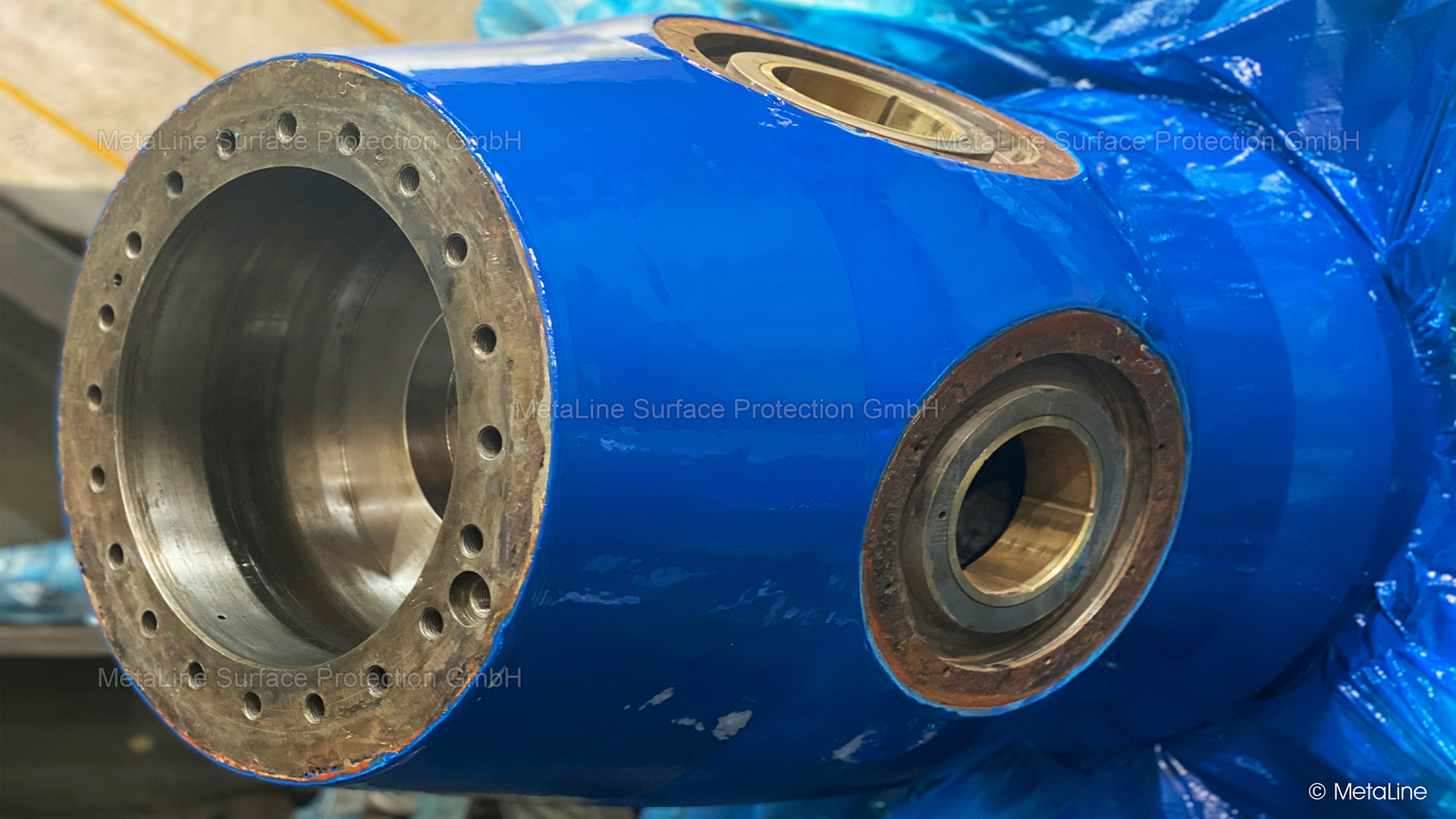

Cavitation protection - we would like to take care of your problems Objectives Resilient, elastic materials are best suited to tolerate alternating push and pull forces. Solid surfaces tend to become brittle or develop partial pitting corrosion. This sooner or later causes dramatic weakening of the component statics and ultimately leads to technical and economic complete failure. Protective coatings from MetaLine make sure that the original component geometry, its basic substances and the required mechanical strength is kept. The coating itself does not have an unlimited lifetime due to these destructive effects. But it may be replaced by far easier and also more cost-effective than the component. Or put in other words, the coating serves as a predetermined wear protection layer recyclable as required. Also, the low area weight amounting to only 1.05 kg/m²/mm and the smooth surface geometry improve the energy efficiency (effectiveness) far better than thermo-metal or ceramic protective systems. Technical solutions in detail MetaLine Series 700 - plane, even and flow-harmonic surfaces to reduce turbulences. Elastic cavitation protection preventing substance degradation – a different way of surface protection.

The permanent change of pressure and tension can best be counteracted by a resilient, elastic material. Otherwise sooner or later a weakening of the static stability can ultimately lead to technical and financial losses. Protective coatings from MetaLine ensure the original component geometry. The mechanical surface strength is kept intact. However, even these specialized coatings have not an unlimited lifetime, given these destructive effects. But it is simpler and less risky – compared to thermal treatments – plus significantly less expensive to replace. Better said, the coating serves as a regenerable wear protection layer that can be renewed at any time. Also, the low area weight amounting to only 1.05 kg/m²/mm (0.22 lbs/ft2/40 mils) and the smooth surface geometry improve the fluid-flow efficiency far better than thermo-metal or ceramic protective systems. MetaLine Series 700 – plane, even and flow-harmonic surfaces to reduce turbulences. Elastic cavitation protection preventing substance degradation – a different surface protection method.